-

×

3970302- 3' Purifier Filtered PCR Enclosure with UV Light and Protection Panel- Labconco

2 × $9,062.00

3970302- 3' Purifier Filtered PCR Enclosure with UV Light and Protection Panel- Labconco

2 × $9,062.00 -

×

19-353-0150 - Omni Bead Ruptor 12 Microtube Adapter, 4-Pack- Omni International

1 × $712.00

19-353-0150 - Omni Bead Ruptor 12 Microtube Adapter, 4-Pack- Omni International

1 × $712.00 -

×

4316 Polypropylene 0.5ml Graduated Flat Top Microcentrifuge Tube, Red Bio Plas

2 × $12.00

4316 Polypropylene 0.5ml Graduated Flat Top Microcentrifuge Tube, Red Bio Plas

2 × $12.00 -

×

HGB550 2-Liter with Stainless Steel Container Waring

1 × $1,151.00

HGB550 2-Liter with Stainless Steel Container Waring

1 × $1,151.00 -

×

VE-B2 BASIC BINOCULAR MICROSCOPE - VELAB

1 × $456.00

VE-B2 BASIC BINOCULAR MICROSCOPE - VELAB

1 × $456.00 -

×

3970223- 2' Purifier Vertical Clean Bench with Airflow Monitor- Labconco

1 × $8,718.15

3970223- 2' Purifier Vertical Clean Bench with Airflow Monitor- Labconco

1 × $8,718.15 -

×

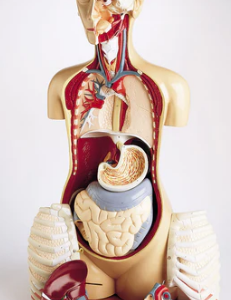

0709-00 Advanced Knowbody Teaching Torso - Denoyer-Geppert

1 × $2,250.00

0709-00 Advanced Knowbody Teaching Torso - Denoyer-Geppert

1 × $2,250.00 -

×

3970300- 3' Purifier Vertical Clean Bench- Labconco

1 × $8,101.75

3970300- 3' Purifier Vertical Clean Bench- Labconco

1 × $8,101.75 -

×

VP200 Vacuum Pump, Universal VAC Hoefer

1 × $3,480.00

VP200 Vacuum Pump, Universal VAC Hoefer

1 × $3,480.00 -

×

V1002-1SL Optional single channel adapter, extra long (80mm) stainless steel Accuris

1 × $33.00

V1002-1SL Optional single channel adapter, extra long (80mm) stainless steel Accuris

1 × $33.00 -

×

3970221- 2' Purifier Vertical Clean Bench with UV Light and Protection Panel- Labconco

1 × $8,242.05

3970221- 2' Purifier Vertical Clean Bench with UV Light and Protection Panel- Labconco

1 × $8,242.05 -

×

81-12531-00, Omega Fluor™ Plus Gel Documentation System, 365 nm Gel Company

1 × $9,670.00

81-12531-00, Omega Fluor™ Plus Gel Documentation System, 365 nm Gel Company

1 × $9,670.00 -

×

9010-0264 FP 240 UL Temperature Test Chamber With Forced Convection Binder

1 × $6,868.00

9010-0264 FP 240 UL Temperature Test Chamber With Forced Convection Binder

1 × $6,868.00 -

×

H5000-025 Block, 48 x 250ul vial insert (6x30mm) Benchmark Scientific

1 × $380.00

H5000-025 Block, 48 x 250ul vial insert (6x30mm) Benchmark Scientific

1 × $380.00 -

×

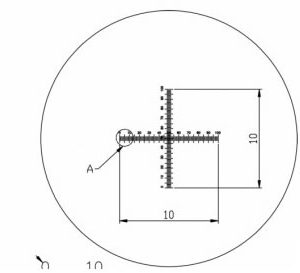

9120010-801 Micrometer reticule Labomed

1 × $75.00

9120010-801 Micrometer reticule Labomed

1 × $75.00 -

×

Acrylamide Powder, 2 x 1 kg - Hoefer

1 × $662.00

Acrylamide Powder, 2 x 1 kg - Hoefer

1 × $662.00 -

×

9020-0338 KBW 240 Growth Chamber with Light, 247L, 200-240V/50Hz/1 ph Binder

1 × $19,329.00

9020-0338 KBW 240 Growth Chamber with Light, 247L, 200-240V/50Hz/1 ph Binder

1 × $19,329.00 -

×

A-105176 Disarticulated Half Child Skeleton Axis Scientific

1 × $280.50

A-105176 Disarticulated Half Child Skeleton Axis Scientific

1 × $280.50 -

×

T3021- Mix & Go! XJa Autolysis Competent Cells, 1 ml 500x L-Arabinose - 10 x 100 µl- Zymo Research

1 × $241.00

T3021- Mix & Go! XJa Autolysis Competent Cells, 1 ml 500x L-Arabinose - 10 x 100 µl- Zymo Research

1 × $241.00 -

×

V1002-S8 Optional eight channel adapter, fine tip stainless steel Accuris

1 × $127.00

V1002-S8 Optional eight channel adapter, fine tip stainless steel Accuris

1 × $127.00 -

×

S61 Premier Academic Series Skeleton, Male, Unpainted, Hanging Mount- Denoyer Geppert

1 × $1,258.00

S61 Premier Academic Series Skeleton, Male, Unpainted, Hanging Mount- Denoyer Geppert

1 × $1,258.00

Subtotal: $90,182.45