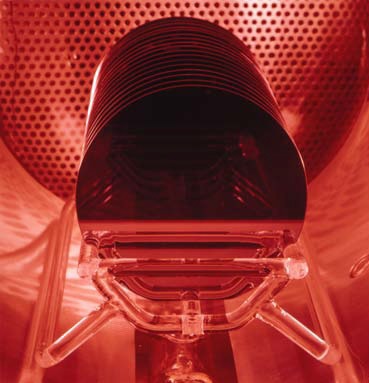

Gas Plasma Reactor, Laboratory Equipment

PR200/PR300-115V/PR300-220V/PR301-115V/PR301-220V- PR Series Standard Gas Plasma Asher – Yamato

$21,722.80 – $36,779.60

Standard barrel type low temperature ashing devices suitable for a wide range of application such as ashing , etching and dry cleaning

Features

- Isotropy barrel type

- Compact, space saving design

- Capable of removing coated organic matter

- Adjustable RF suitable for various applications

- Outstanding operability and safety

- Can be set for a wide range of output conditions to handle a variety of testing samples

Applications

- Functionalization of the polymeric material surface improves adhesion

- Oxidation reaction generates functional groups -OH, >C=O, -COOH on the surface (very small amount of water and carbon dioxide will impact)

- In nitrogen plasma, a nitrogen atom is incorporated onto the surface, generates a functional group -NH₂ Resist peeling

- Surface modification of materials (metals, polymers, films, ceramics, etc.)

- Asbestos pre-processing (ashing of membrane filter)

- Low-temperature ashing (polymer material, coal, food, etc.) PDMS chips bonding to glass and PDMS substrate

- Production of semiconductors and analysis work

| Models | PR200 | PR300-115V PR300-220V |

PR301-115V PR301-220V |

|

| Plasma Mode | Direct plasma (DP) | Direct plasma (DP) | Direct plasma (DP) | |

| High Frequency Output | Max. 200W | Max. 300W (100W x 3 chambers) | Max. 300W | |

| Oscillation Frequency | 13.56MHz | |||

| Tuning Method | Auto matching | Manual biaxial | Manual biaxial | |

| Reaction Chamber (Pyrex Glass) | ø100×160mm x 1 chamber | ø64×160mm × 3 chambers | ø118×160mm x 1 chamber | |

| Reaction Gas | 1 system (oxygen), flow meter control with dry air purge gas | |||

| Control System | Manual leak valve | Auto pressure reduction, auto leak valve | ||

| Piping Material | Stainless steel, Teflon | Stainless steel, Teflon, Copper and Brass | Stainless steel, Teflon | |

| External Dimensions WxDxH | 350x400x500 mm | 438×520×556 mm | 438×520×660 mm | |

| Weight | ~25kg | ~36kg | ~34kg | |

| Power Source 50/60Hz | AC115V 13A | AC115V 6.1A AC220V 3.2A |

AC115V 6.1A AC220V 3.2A |

|

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Products | PR-200 (GAS PLASMA REACTOR 115V), PR-300-115V (GAS PLASMA REACTOR 115V), PR-300-220V (GAS PLASMA REACTOR 220V), PR-301-115V (GAS PLASMA REACTOR 115V), PR-301-220V (GAS PLASMA REACTOR 220V) |